Upgrading Torque Capacity. Weak K2 Clutch Pack.

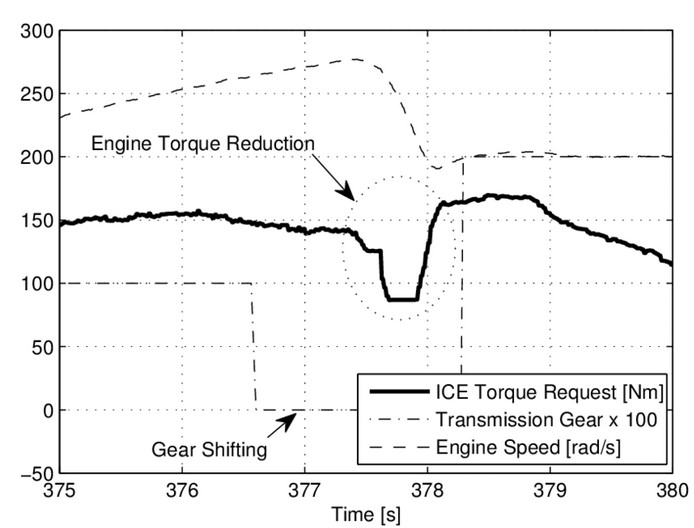

EGS52 system uses ignition timing control to reduce torque during shifts since this is a clutch-to-clutch transmission to make shifts faster and keep clutches from being overheated from too much torque input during the shift phase and faster crisper shifts.

Turning off torque reduction during WOT will not make you any faster but more stress on clutches and could cause heat marks on clutch steels due to too much torque during shift phase. We reduce torque reduction below 250nm and raise it above 450nm.

Raising Torque Capacity:

Some older transmissions will have double-sided clutches for k1-b1-k3.

K1 clutch pack has 10 single-sided clutches, you can install 12 single-sided by machining the piston down. For 1-2 shift but unless you are on drag slicks and huge power no reason to modify this clutch pack.

K2 clutch pack is the weak link due to double sided clutches (6 frictions) with thin steels without torque reduction for 2-3 shift these clutches will burn out very quickly with a modified engine with very little reduction in torque during wot shifts.. Stock tcu reduction of torque is NOT enough for 2-3 shift and gradually k2 clutches will cause burn spots to steels and clutch material will turn black then eventually will start slipping. We raise up 2-3 torque reduction and limit amount of torque for k2 to a point with v12 specs. Will sooner or later wear out.

Way to solve K2 clutch issue is to add more frictions. K2 piston will need to be machined down to allow for 1 more friction and steel and run tight clearances of .059 without using factory compression tool with 7 clutches.

K2 with 7 frictions ads torque capacity to clutch pack that will greatly reduce heat build up and live longer behind highly modded engines.

“New clutches” we have measured each clutch loses .001-.002 clearance after the break-in period opens up clearances a tad more. So 7 frictions after break-in usually .007-.014 more clearance to clutch pack is the reason why we run them tight when using new frictions and fall right into the lower end of factory specs.

K3 clutch pack can be expanded to 12 single-sided clutches if you are pushing huge power for 3-4 shift, using v12 basket will only need piston machined down, using standard v8 basket piston will need machined down and also step machined into backing plate to get correct clearances. We like to set them at .050 on tight side due to new clutches lose thickness after break-in and u end up with a little over .060 clearance witch would put it at around .099 using factory compression tool witch puts it into spec on tight end that works great for my sequential tune.

B1 No need to do anything with. Only holds power in 5th.

B2 No need to mess with unless pushing huge power witch will require backing plate machined for extra clutch but could cause coning or snap-ring grove machined out works also. This is if your pushing huge power.

B3 No need to modify.

Leave a Reply

You must be logged in to post a comment.